: +86-13181986275 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

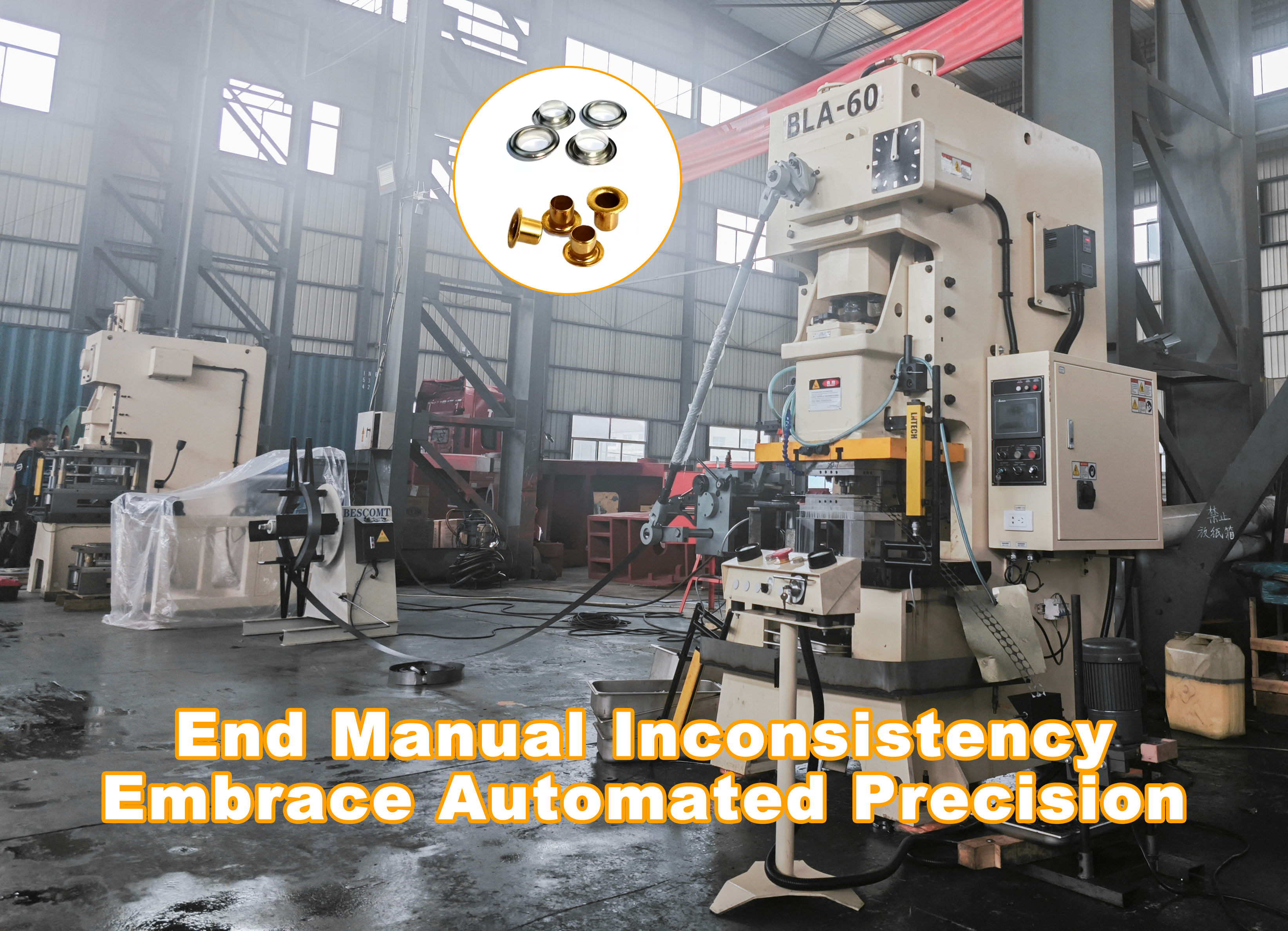

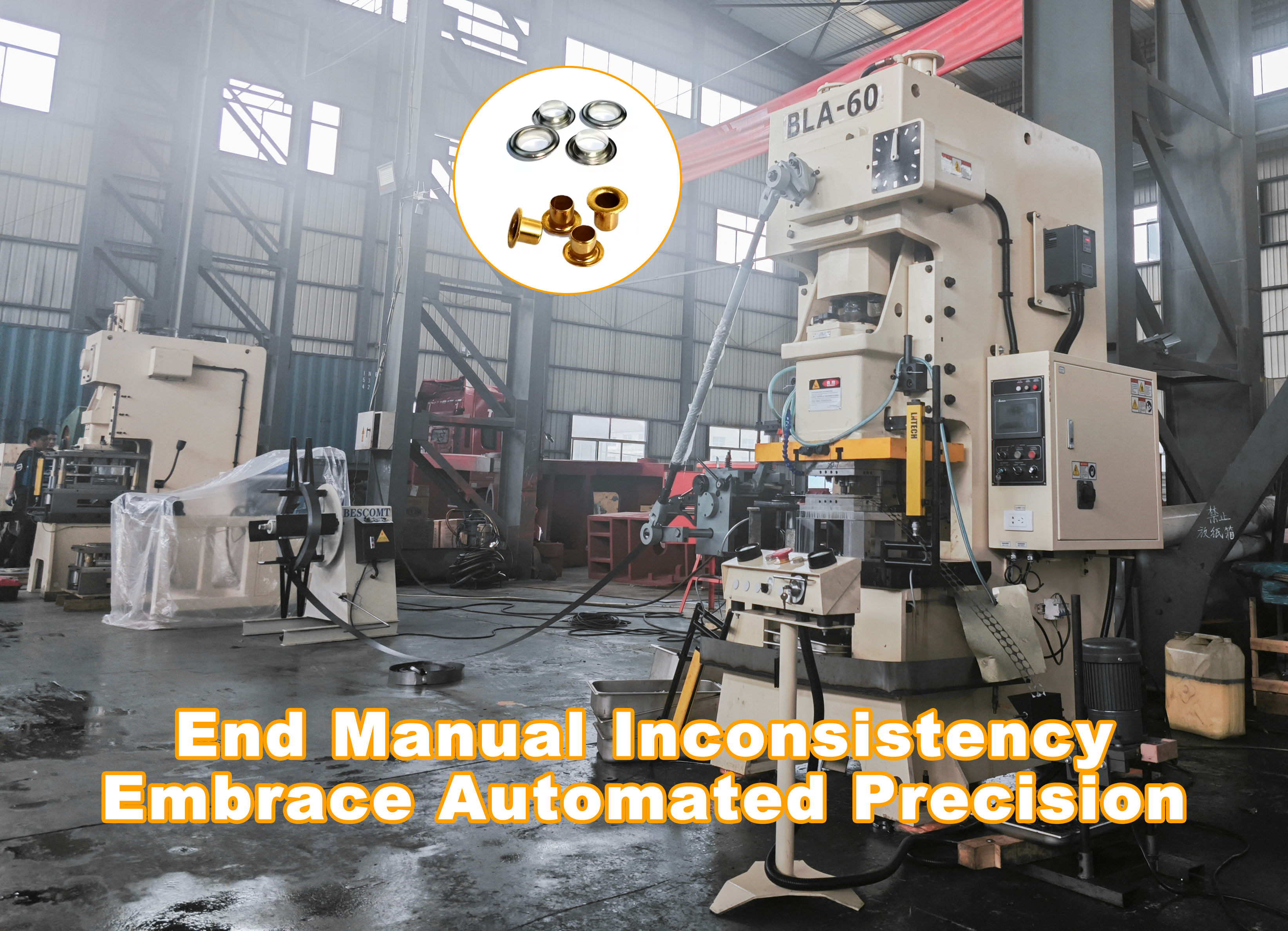

Is your eyelet punching process slowed by misaligned holes, tired operators, or inconsistent quality? Our High-Speed Automatic Feed Eyelet Punching Machine delivers precision performance. Built for stainless steel and aluminum, it combines punching and feeding in one fast, accurate cycle. Increase output, reduce errors, and maintain perfect results every shift.

Material rack

Pneumatic press

Product mold

High Speed Roll Feeder

Advantages of the machine:

1. Body material: use high strength steel, hard chrome plated to make sure of high precision.

2. Lubrication system: special structure with automatic closed lubrication, special industrial design so those main bodies get quicker and more natural cooling.

3. Equipped with reverse dynamic balanced device to realize high speed operation and prolong useful life of main parts.

4. Computer control system: display working status and fault. Top dead center control to remove fault easily.

5. Air pressure system: use with standard parts to make system stable.

6. Adjustment mould operation control system, separate structure and function to be safer, stable and precision.

7. For main system (air, lubrication and air pressure locked) equipped with pressure show and pressure switch protector device to make all system more stable.

8. Use with force cooling circulation system in the main parts to prefect transfer mechanism, meanwhile prolong useful life.

9. Equipped with location direction for direction device to be more precision, easy test and repair.

Name | Unit | RC21G-16 | RC21G-25 | RC21G-45 | RC21G-60 |

Nominal Pressure | KN | 160 | 250 | 450 | 600 |

Nominal Power Stroke | mm | 1.5 | 1.5 | 1.5 | 1.5 |

Stroke of slide | mm | 20 | 20 | 20 | 20 |

Strokes | S.PM | 150-500 | 150-500 | 150-450 | 150-400 |

Max Die Set Hight | mm | 200 | 220 | 250 | 280 |

Die Height Adjustment | mm | 50 | 50 | 50 | 50 |

Depth of Throat | mm | 160 | 190 | 235 | 270 |

Distance Between the Pillars | mm | 260 | 300 | 350 | 400 |

Bottom Size of Slide | (L-R)mm | 350 | 400 | 460 | 540 |

(F-B)mm | 240 | 270 | 300 | 350 | |

Size of Table | (L-R)mm | 600 | 660 | 720 | 850 |

(F-B)mm | 300 | 360 | 450 | 520 | |

Mian Motor Power | KW | 3 | 4 | 7.5 | 11 |

Dimensions | (L-R)mm | 900 | 945 | 1080 | 1245 |

(F-B)mm | 1452 | 1475 | 1620 | 1890 | |

Height | 1920 | 2045 | 2405 | 2675 |

This machine is the heart of efficiency for businesses that rely on secure, reinforced holes:

·Metal & Hardware: Nameplates, toolboxes, metal cabinets, ventilation grilles.

·Outdoor & Textile Gear: Tents, awnings, backpacks, belts, canvas products.

·Automotive & Wiring Harnesses: Grommets for wiring, metal bushings.

·Leather Goods: Decorative and functional eyelets on premium leather.

Is your eyelet punching process slowed by misaligned holes, tired operators, or inconsistent quality? Our High-Speed Automatic Feed Eyelet Punching Machine delivers precision performance. Built for stainless steel and aluminum, it combines punching and feeding in one fast, accurate cycle. Increase output, reduce errors, and maintain perfect results every shift.

Material rack

Pneumatic press

Product mold

High Speed Roll Feeder

Advantages of the machine:

1. Body material: use high strength steel, hard chrome plated to make sure of high precision.

2. Lubrication system: special structure with automatic closed lubrication, special industrial design so those main bodies get quicker and more natural cooling.

3. Equipped with reverse dynamic balanced device to realize high speed operation and prolong useful life of main parts.

4. Computer control system: display working status and fault. Top dead center control to remove fault easily.

5. Air pressure system: use with standard parts to make system stable.

6. Adjustment mould operation control system, separate structure and function to be safer, stable and precision.

7. For main system (air, lubrication and air pressure locked) equipped with pressure show and pressure switch protector device to make all system more stable.

8. Use with force cooling circulation system in the main parts to prefect transfer mechanism, meanwhile prolong useful life.

9. Equipped with location direction for direction device to be more precision, easy test and repair.

Name | Unit | RC21G-16 | RC21G-25 | RC21G-45 | RC21G-60 |

Nominal Pressure | KN | 160 | 250 | 450 | 600 |

Nominal Power Stroke | mm | 1.5 | 1.5 | 1.5 | 1.5 |

Stroke of slide | mm | 20 | 20 | 20 | 20 |

Strokes | S.PM | 150-500 | 150-500 | 150-450 | 150-400 |

Max Die Set Hight | mm | 200 | 220 | 250 | 280 |

Die Height Adjustment | mm | 50 | 50 | 50 | 50 |

Depth of Throat | mm | 160 | 190 | 235 | 270 |

Distance Between the Pillars | mm | 260 | 300 | 350 | 400 |

Bottom Size of Slide | (L-R)mm | 350 | 400 | 460 | 540 |

(F-B)mm | 240 | 270 | 300 | 350 | |

Size of Table | (L-R)mm | 600 | 660 | 720 | 850 |

(F-B)mm | 300 | 360 | 450 | 520 | |

Mian Motor Power | KW | 3 | 4 | 7.5 | 11 |

Dimensions | (L-R)mm | 900 | 945 | 1080 | 1245 |

(F-B)mm | 1452 | 1475 | 1620 | 1890 | |

Height | 1920 | 2045 | 2405 | 2675 |

This machine is the heart of efficiency for businesses that rely on secure, reinforced holes:

·Metal & Hardware: Nameplates, toolboxes, metal cabinets, ventilation grilles.

·Outdoor & Textile Gear: Tents, awnings, backpacks, belts, canvas products.

·Automotive & Wiring Harnesses: Grommets for wiring, metal bushings.

·Leather Goods: Decorative and functional eyelets on premium leather.