: +86-18155523399 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

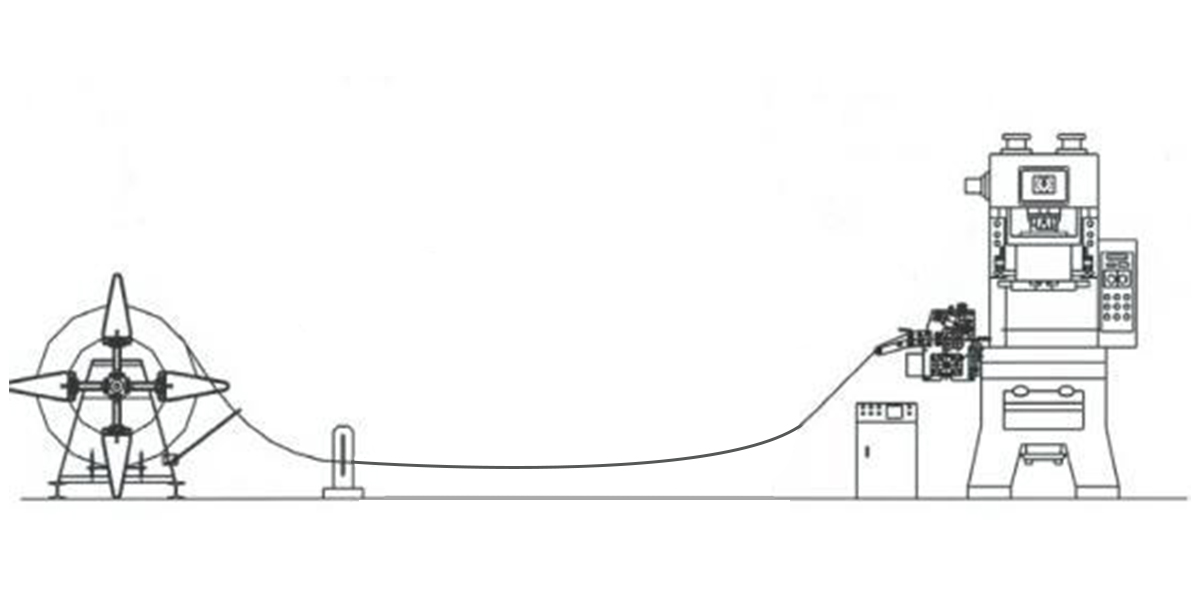

This fully automatic LED bulb cover assembly line integrates a high-rigidity material rack, precision servo feeding system, efficient pneumatic press, and customized dies, specifically designed for feeding, punching, cutting, folding, or assembling plastic lamp covers. It achieves one-stop automated production from coil/sheet material to finished products. It is the ideal solution for LED manufacturers to boost output, ensure consistency, and reduce labor costs.

Component 1: Intelligent Material Rack System

Heavy-duty capacity, stable unwinding, and compatibility with various coil/sheet sizes.

Component 2: High-Precision Servo Feeder

Precise feeding, perfectly synchronized with press speed, supporting multiple feed lengths.

Component 3: Pneumatic Press

Consistent impact force, low noise, and simple operation and maintenance.

Component 4: Customized Precision Mold

Custom-built to your product drawings, ensuring one-step forming and precise dimensions.

We can provide matching E27 lamp caps and A60 lamp cups, or customize them according to customer needs and budget.

✅ Service Package:

·Free installation & training

·2-year warranty on all parts

·24-hour technical support

·Free online training videos

�� Ready to Calculate YOUR Exact ROI?

Step 1: Watch Demo Video

[▶️ CLICK TO SEE LIVE PRODUCTION]

Step 2: Get Free Production Analysis

"Share your current production details, and our engineers will provide a customized efficiency report."

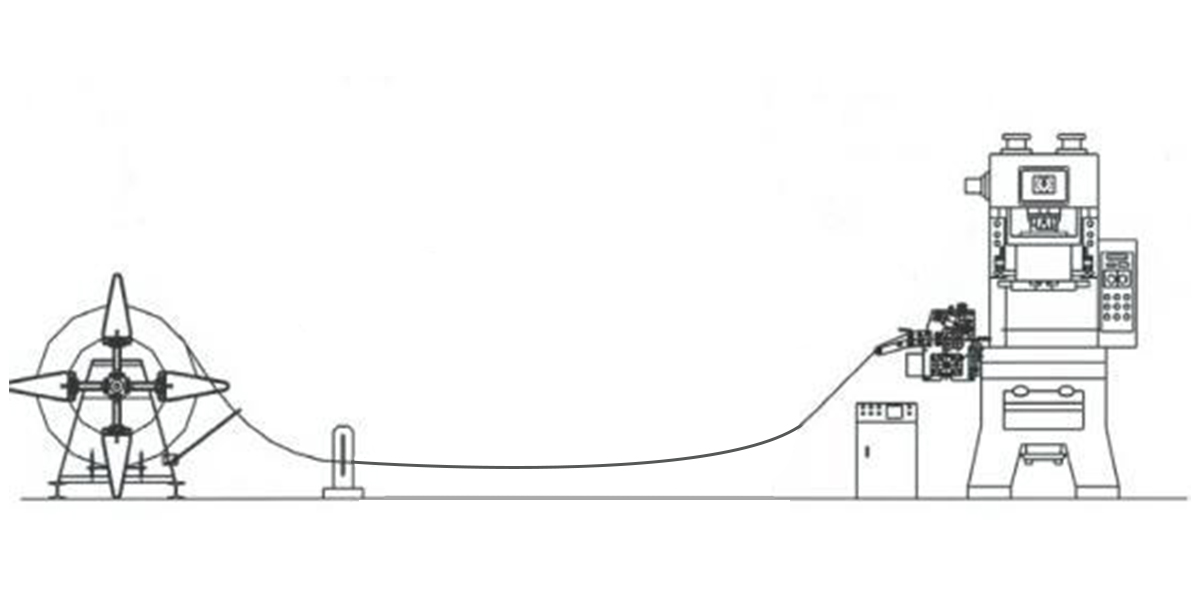

This fully automatic LED bulb cover assembly line integrates a high-rigidity material rack, precision servo feeding system, efficient pneumatic press, and customized dies, specifically designed for feeding, punching, cutting, folding, or assembling plastic lamp covers. It achieves one-stop automated production from coil/sheet material to finished products. It is the ideal solution for LED manufacturers to boost output, ensure consistency, and reduce labor costs.

Component 1: Intelligent Material Rack System

Heavy-duty capacity, stable unwinding, and compatibility with various coil/sheet sizes.

Component 2: High-Precision Servo Feeder

Precise feeding, perfectly synchronized with press speed, supporting multiple feed lengths.

Component 3: Pneumatic Press

Consistent impact force, low noise, and simple operation and maintenance.

Component 4: Customized Precision Mold

Custom-built to your product drawings, ensuring one-step forming and precise dimensions.

We can provide matching E27 lamp caps and A60 lamp cups, or customize them according to customer needs and budget.

✅ Service Package:

·Free installation & training

·2-year warranty on all parts

·24-hour technical support

·Free online training videos

�� Ready to Calculate YOUR Exact ROI?

Step 1: Watch Demo Video

[▶️ CLICK TO SEE LIVE PRODUCTION]

Step 2: Get Free Production Analysis

"Share your current production details, and our engineers will provide a customized efficiency report."

machine type | Punching Machine | power source | Pneumatic |

voltage | 380V/220V | cnc or not | CNC |

core components | Gear, Motor, PLC | key selling points | High Productivity |

warranty | 2 Years | machinery test report | Provided |

video outgoinginspection | Provided | motor power (kw) | 11 |

place of origin | Shandong, China | weight (t) | 9.6 |

slide stroke (mm) | 180 | brand name | BESCO |

dimension(I*w*h) | 1900*1300*3200 | Product name | lamp cup production line |

Application | Stamping | Function | lamp cup making machine |

Type | C-Type Structure | After-sales Service Provided | Overseas Service Provided |

Power Press | Pneumatic Stamping Press | Advantage | High Efficiceny |

Control system | PLC | Brand | BESCO |

Control | pneumatic | ||

machine type | Punching Machine | power source | Pneumatic |

voltage | 380V/220V | cnc or not | CNC |

core components | Gear, Motor, PLC | key selling points | High Productivity |

warranty | 2 Years | machinery test report | Provided |

video outgoinginspection | Provided | motor power (kw) | 11 |

place of origin | Shandong, China | weight (t) | 9.6 |

slide stroke (mm) | 180 | brand name | BESCO |

dimension(I*w*h) | 1900*1300*3200 | Product name | lamp cup production line |

Application | Stamping | Function | lamp cup making machine |

Type | C-Type Structure | After-sales Service Provided | Overseas Service Provided |

Power Press | Pneumatic Stamping Press | Advantage | High Efficiceny |

Control system | PLC | Brand | BESCO |

Control | pneumatic | ||

content is empty!