: +86-18155523399 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Metal Air Conditioner Bracket Stamping Press Production Line

BESCOMT

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Bescomt metal bracket stamping production line is a sheet metal processing system that combines automation, high precision, and high efficiency. It is designed for the large-scale production of various metal brackets, such as air conditioner brackets, solar brackets, and automotive component brackets. Utilizing servo drive technology, an intelligent control system, and a modular mold design, the line can accommodate stamping requirements for a variety of materials (cold-rolled steel, galvanized steel, aluminum alloy, etc.) and thicknesses, ensuring product consistency and high yield.

The punch press utilizes a highly rigid C-shaped frame with precision guides, achieving a repeatable positioning accuracy of ±0.02mm, ensuring precise bracket hole placement and bending angles to meet stringent assembly requirements. The line supports quick die change and is compatible with a wide range of bracket molds. Its servo motor drive reduces energy consumption by 30% compared to traditional hydraulic presses, eliminates oil pollution, and maintains a noise level of ≤75dB, meeting CE/ISO environmental standards.

Product Advantage

High precision:

The processing accuracy is high, the dimensions are precise, and the surface is smooth, which meets the requirements for high-quality processing production.

High efficiency:

The speed is fast, the energy consumption is low, and the comprehensive efficiency is high, effectively shortening the production cycle.

High reliability:

The operation is stable, the defective rate is low, the mold life is long, and the maintenance cost is low.

High flexibility:

They support integrated automation, have adjustable parameters, and can adapt to the production of various specifications.

Customization:

We provide exclusive equipment configurations to meet the production needs of different customers.

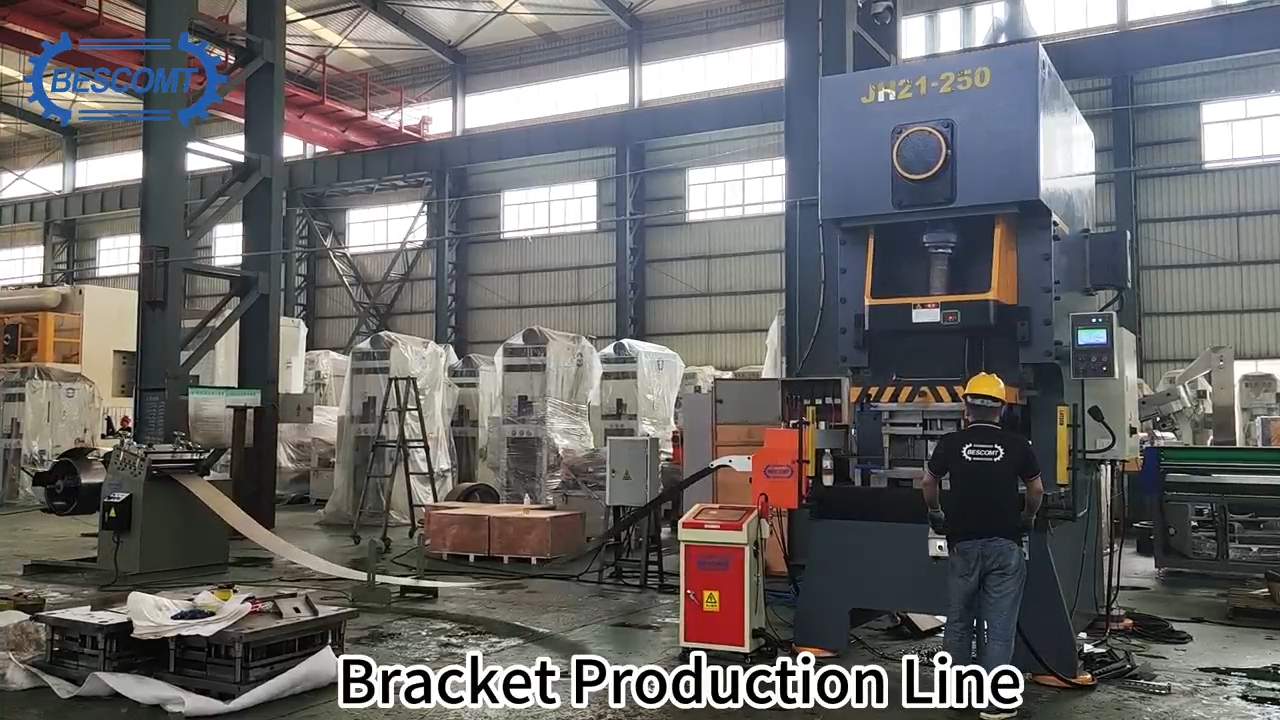

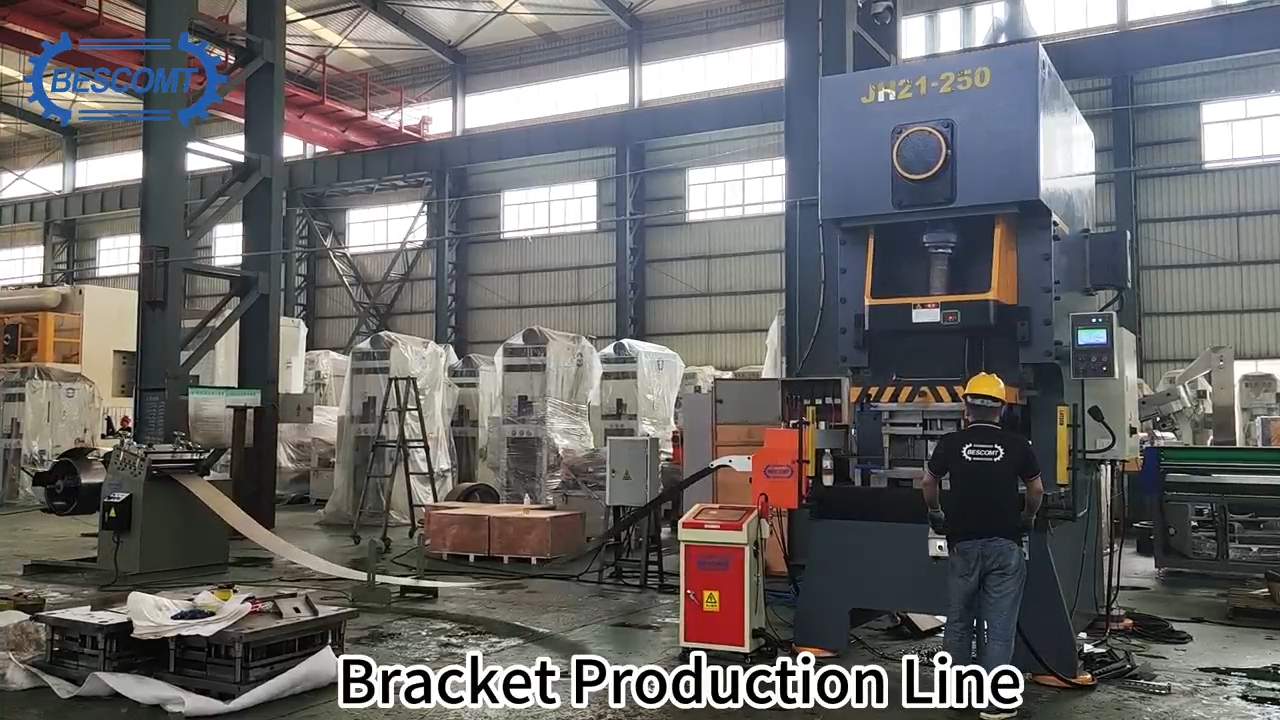

Photo Show

Applicable industries

1. Home Appliance Manufacturing: Air Conditioner Brackets (Wall-Mount/Outdoor Unit Brackets), Refrigerator Compressor Brackets, Washing Machine Balancer Brackets

2. Automotive Parts: Engine Brackets, Exhaust Pipe Hangers, Chassis Reinforcement Brackets

3. Construction and Building Materials: Steel Structure Connecting Brackets, Curtain Wall Fixing Brackets, Pipe Support Brackets

4. Electronic Equipment: Server Cabinet Brackets, Industrial Control Box Mounting Brackets

5. New Energy Sector: Solar Panel Brackets, Battery Pack Fixing Brackets

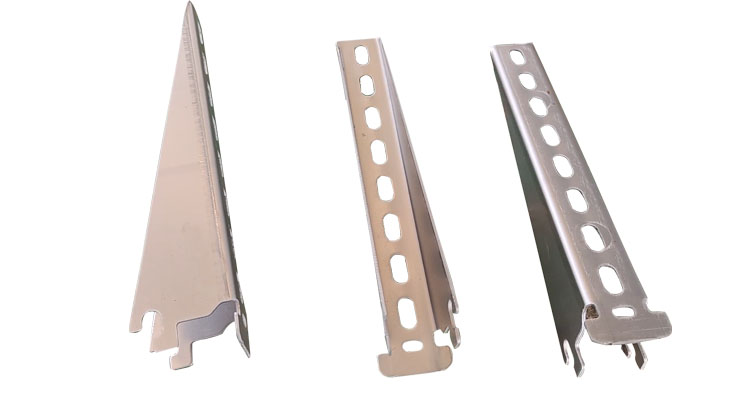

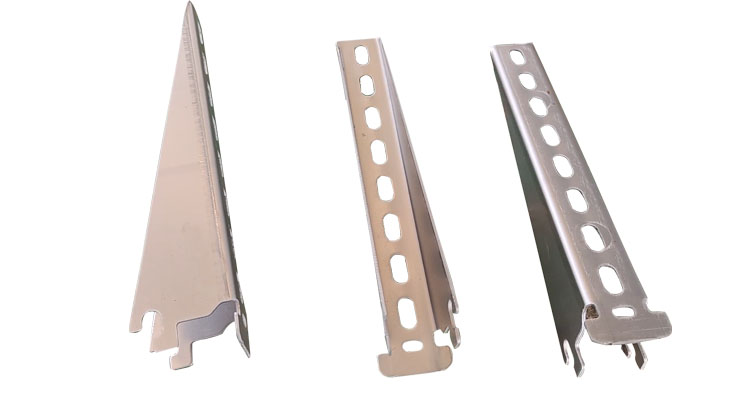

Samples Show

Video Show

Product Description

Bescomt metal bracket stamping production line is a sheet metal processing system that combines automation, high precision, and high efficiency. It is designed for the large-scale production of various metal brackets, such as air conditioner brackets, solar brackets, and automotive component brackets. Utilizing servo drive technology, an intelligent control system, and a modular mold design, the line can accommodate stamping requirements for a variety of materials (cold-rolled steel, galvanized steel, aluminum alloy, etc.) and thicknesses, ensuring product consistency and high yield.

The punch press utilizes a highly rigid C-shaped frame with precision guides, achieving a repeatable positioning accuracy of ±0.02mm, ensuring precise bracket hole placement and bending angles to meet stringent assembly requirements. The line supports quick die change and is compatible with a wide range of bracket molds. Its servo motor drive reduces energy consumption by 30% compared to traditional hydraulic presses, eliminates oil pollution, and maintains a noise level of ≤75dB, meeting CE/ISO environmental standards.

Product Advantage

High precision:

The processing accuracy is high, the dimensions are precise, and the surface is smooth, which meets the requirements for high-quality processing production.

High efficiency:

The speed is fast, the energy consumption is low, and the comprehensive efficiency is high, effectively shortening the production cycle.

High reliability:

The operation is stable, the defective rate is low, the mold life is long, and the maintenance cost is low.

High flexibility:

They support integrated automation, have adjustable parameters, and can adapt to the production of various specifications.

Customization:

We provide exclusive equipment configurations to meet the production needs of different customers.

Photo Show

Applicable industries

1. Home Appliance Manufacturing: Air Conditioner Brackets (Wall-Mount/Outdoor Unit Brackets), Refrigerator Compressor Brackets, Washing Machine Balancer Brackets

2. Automotive Parts: Engine Brackets, Exhaust Pipe Hangers, Chassis Reinforcement Brackets

3. Construction and Building Materials: Steel Structure Connecting Brackets, Curtain Wall Fixing Brackets, Pipe Support Brackets

4. Electronic Equipment: Server Cabinet Brackets, Industrial Control Box Mounting Brackets

5. New Energy Sector: Solar Panel Brackets, Battery Pack Fixing Brackets

Samples Show

Video Show

| Model | Unit | JH-80T | JH-125T | JH-160T | JH-200T | JH-250T |

| Norminal Pressure | kn | 800 | 1250 | 1600 | 2000 | 2500 |

| Norminal Pressure Stroke | mm | 5 | 5 | 6 | 6 | 7 |

| Slide Stroke | mm | 160 | 180 | 200 | 180 | 250 |

| Max die Height | mm | 320 | 350 | 400 | 390 | 500 |

| Die Height Adjustment | mm | 80 | 90 | 100 | 110 | 120 |

| Distance From Slide Block To Frame | mm | 310 | 350 | 390 | 390 | 450 |

| Distance Between uprights | mm | 620 | 660 | 720 | 870 | 980 |

| Slide Surface Size | mm | 540*460 | 620*520 | 700*580 | 800*600 | 950*700 |

| Hole Size For Die Handel | mm | 50*90 | 70*90 | 70*100 | 70*90 | 70*100 |

| Bloster Size | mm | 950*600 | 1070*680 | 1170*760 | 1400*760 | 1500*880 |

| Blanking Hole Size | mm | 150 | 160 | 180 | 300 | 200 |

| Worktable Distance | mm | 900 | 900 | 900 | 900 | 1000 |

| Motor Power | kw | 7.5 | 11 | 15 | 18.5 | 22 |

| Dimension | mm | 2125*1760*3040 | 2355*1875*3255 | 2380*1450*3250 | 2550*1580*3320 | 2820*1710*3900 |

| Weight | kg | 6600 | 10500 | 12800 | 18000 | 23900 |

| Model | Unit | JH-80T | JH-125T | JH-160T | JH-200T | JH-250T |

| Norminal Pressure | kn | 800 | 1250 | 1600 | 2000 | 2500 |

| Norminal Pressure Stroke | mm | 5 | 5 | 6 | 6 | 7 |

| Slide Stroke | mm | 160 | 180 | 200 | 180 | 250 |

| Max die Height | mm | 320 | 350 | 400 | 390 | 500 |

| Die Height Adjustment | mm | 80 | 90 | 100 | 110 | 120 |

| Distance From Slide Block To Frame | mm | 310 | 350 | 390 | 390 | 450 |

| Distance Between uprights | mm | 620 | 660 | 720 | 870 | 980 |

| Slide Surface Size | mm | 540*460 | 620*520 | 700*580 | 800*600 | 950*700 |

| Hole Size For Die Handel | mm | 50*90 | 70*90 | 70*100 | 70*90 | 70*100 |

| Bloster Size | mm | 950*600 | 1070*680 | 1170*760 | 1400*760 | 1500*880 |

| Blanking Hole Size | mm | 150 | 160 | 180 | 300 | 200 |

| Worktable Distance | mm | 900 | 900 | 900 | 900 | 1000 |

| Motor Power | kw | 7.5 | 11 | 15 | 18.5 | 22 |

| Dimension | mm | 2125*1760*3040 | 2355*1875*3255 | 2380*1450*3250 | 2550*1580*3320 | 2820*1710*3900 |

| Weight | kg | 6600 | 10500 | 12800 | 18000 | 23900 |

content is empty!