: +86-18155523399 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Multi station CNC lathe

BESCOMT

| Availability: | |

|---|---|

| Quantity: | |

1. Product Introduction

Multi position precision machining lathe is an efficient and high-precision CNC machine tool, which is mainly used for batch production of complex parts. Its core feature is that through the collaborative work of multiple processing stations, it can complete multiple processes at one time, so as to significantly improve the processing efficiency and accuracy.

2. Product Advantage

3. Product Uses

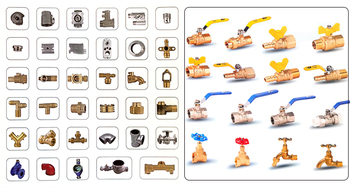

The CNC lathe produced by our company can carry out multi position finish machining for various types of copper valves, which is suitable for ball valves, gate valves, globe valves, check valves, safety valves, angle valves, thermostatic valves, pressure reducing valves and other valves. It can be used for tapping, drilling, turning, milling and other composite processes, so as to realize integrated mass production.

4. Product Video

5. Customer Reviews

1. Product Introduction

Multi position precision machining lathe is an efficient and high-precision CNC machine tool, which is mainly used for batch production of complex parts. Its core feature is that through the collaborative work of multiple processing stations, it can complete multiple processes at one time, so as to significantly improve the processing efficiency and accuracy.

2. Product Advantage

3. Product Uses

The CNC lathe produced by our company can carry out multi position finish machining for various types of copper valves, which is suitable for ball valves, gate valves, globe valves, check valves, safety valves, angle valves, thermostatic valves, pressure reducing valves and other valves. It can be used for tapping, drilling, turning, milling and other composite processes, so as to realize integrated mass production.

4. Product Video

5. Customer Reviews

| Machine dimension | 3200x2300x2500(mm) |

| Net weight | >6T |

| Power supply | Three-phase four-wire |

| Processing time | 6-12pcs/min |

| Loading and unloading method | Manual/Manipulator |

| Number of clamps | >6pcs |

| Hydraulic pressure | 3.0-3.5mpa |

| Machined work material | Copper,Aluminum,Cast iron,Zinc alloy |

| Processing method | Three-way one-time |

| Spindle layout | As the product do plans |

| Machine dimension | 3200x2300x2500(mm) |

| Net weight | >6T |

| Power supply | Three-phase four-wire |

| Processing time | 6-12pcs/min |

| Loading and unloading method | Manual/Manipulator |

| Number of clamps | >6pcs |

| Hydraulic pressure | 3.0-3.5mpa |

| Machined work material | Copper,Aluminum,Cast iron,Zinc alloy |

| Processing method | Three-way one-time |

| Spindle layout | As the product do plans |