: +86-18155523399 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

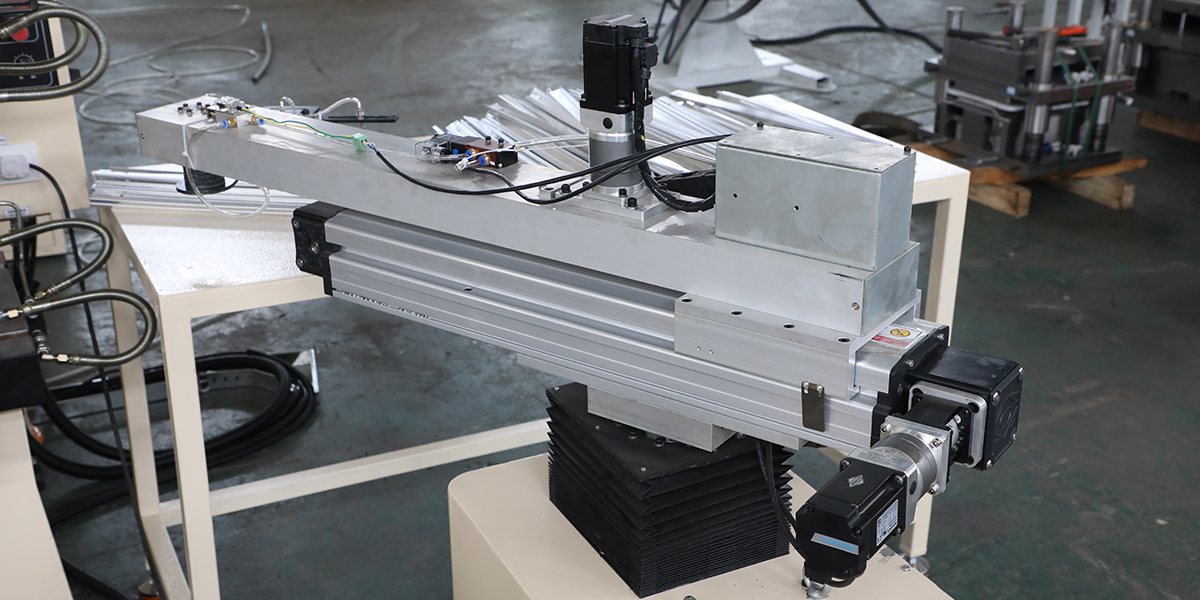

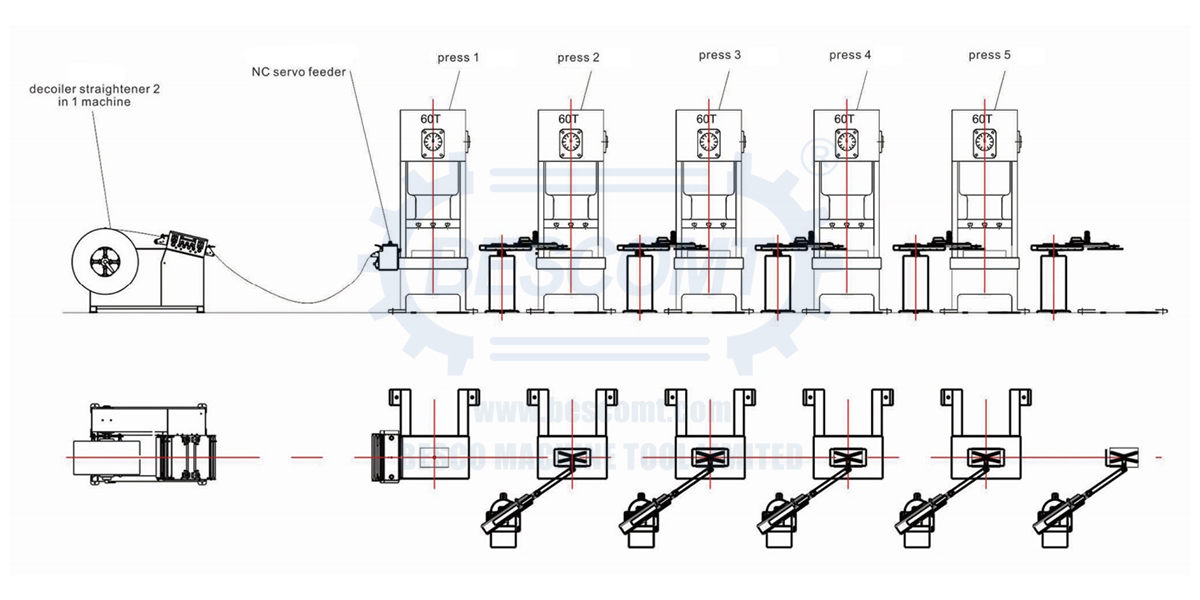

A 4-axis robotic arm is a cost-effective industrial automation solution with four degrees of freedom, excelling in repetitive tasks like machine tending, pick-and-place, and palletizing. It offers high repeatability (often within ±0.1mm), speeds up to 15 cycles per minute, and features simple programming methods like drag-and-teach. Its compact design saves space, making it ideal for automating production lines to boost efficiency, ensure consistency, and reduce labor costs in manufacturing

1、Characteristic

·Robot special use action control system, safely, steady and high efficiency.

·OAdopted Chinese operate system, touch screen in HMI, easy to learn and operate.

·OAll axes were driven by AC servo motor.

·OIndependent research and development, patented technology.

·Other issues:

(1)installing methd: ground

(2)Max. loading capacity: 5kg

(3)Re-orientation accuracy_+0.2mm

(4)Production fregnency: 10-14 times/rain

(5)Environment tempreture: 0-50℃

(6)Humidity: 30%-95%

|  |  |

2、Introduces the configuration and technical parameters of the robot (three or four, five axis) R

| Main axis going up and down | Transfer arm stretching out and drawing back J3 | Arm terminus rolling over part J5 |

1. Serve motor with brake(Z set) 2. 2. Ball screw + liner quide 3. Distance of run:0-350mm/250mm | 1. Servo motor(1 set) 2. Lead screw and synchronous belt transmission 3. Distance of run: 600mm | 1. Servo motor(1 set) 2. High precision planet reducer 3. Rolling over range: ±220° |

| Rotating axle in entirety | Transfer arm rotating horizontally J4 | N.B.Specifications are subject to change without notice. |

1. Serve meter(1 set) 2. High precision harmonic speed reducer 3. Rotating range:± 180° 4. activity radius: 1300mm-1800mm | 1. Servo motor(1 set) 2. High precision planet reducer 3. Rotating range:±180° |

3、Call to Action:

Upgrade your production today! Contact us for a free on-site assessment and a customized automation solution. Let's calculate your ROI!

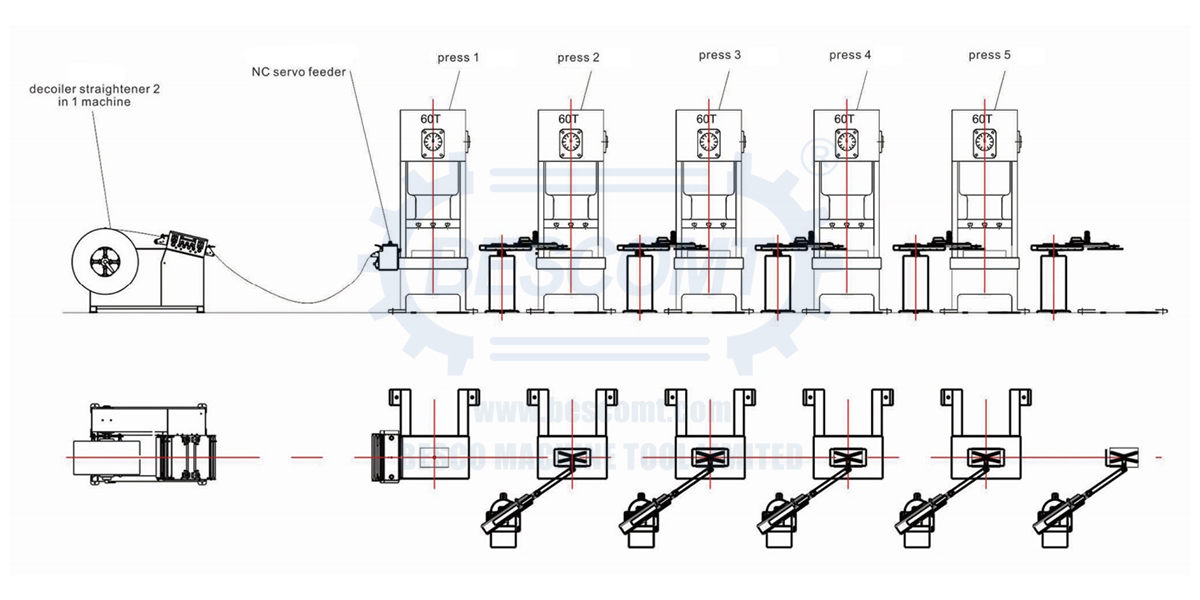

A 4-axis robotic arm is a cost-effective industrial automation solution with four degrees of freedom, excelling in repetitive tasks like machine tending, pick-and-place, and palletizing. It offers high repeatability (often within ±0.1mm), speeds up to 15 cycles per minute, and features simple programming methods like drag-and-teach. Its compact design saves space, making it ideal for automating production lines to boost efficiency, ensure consistency, and reduce labor costs in manufacturing

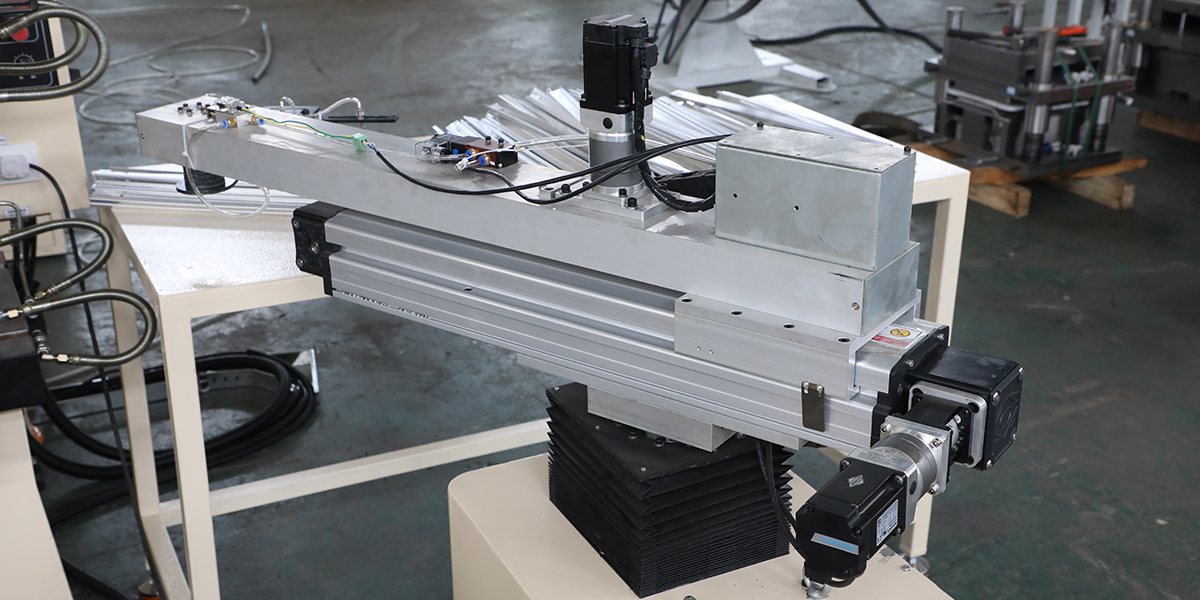

1、Characteristic

·Robot special use action control system, safely, steady and high efficiency.

·OAdopted Chinese operate system, touch screen in HMI, easy to learn and operate.

·OAll axes were driven by AC servo motor.

·OIndependent research and development, patented technology.

·Other issues:

(1)installing methd: ground

(2)Max. loading capacity: 5kg

(3)Re-orientation accuracy_+0.2mm

(4)Production fregnency: 10-14 times/rain

(5)Environment tempreture: 0-50℃

(6)Humidity: 30%-95%

|  |  |

2、Introduces the configuration and technical parameters of the robot (three or four, five axis) R

| Main axis going up and down | Transfer arm stretching out and drawing back J3 | Arm terminus rolling over part J5 |

1. Serve motor with brake(Z set) 2. 2. Ball screw + liner quide 3. Distance of run:0-350mm/250mm | 1. Servo motor(1 set) 2. Lead screw and synchronous belt transmission 3. Distance of run: 600mm | 1. Servo motor(1 set) 2. High precision planet reducer 3. Rolling over range: ±220° |

| Rotating axle in entirety | Transfer arm rotating horizontally J4 | N.B.Specifications are subject to change without notice. |

1. Serve meter(1 set) 2. High precision harmonic speed reducer 3. Rotating range:± 180° 4. activity radius: 1300mm-1800mm | 1. Servo motor(1 set) 2. High precision planet reducer 3. Rotating range:±180° |

3、Call to Action:

Upgrade your production today! Contact us for a free on-site assessment and a customized automation solution. Let's calculate your ROI!