: +86-18155523399 : jerry.yan@bescomt.com : Request A Quote

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

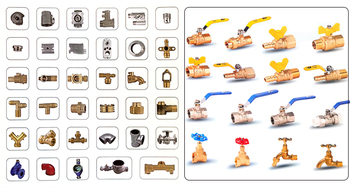

Shandong BESCOMT Machine Tool Equipment Co., Ltd. in China has launched a new generation of fully automated copper valve production line, with intelligent equipment cluster as the core, to achieve one-stop closed-loop production of copper valve processing from raw materials to finished products! This production line integrates seven core processes, including copper bar cutting, hot forming, and precision machining, to meet the manufacturing needs of copper valves in various fields such as bathroom, industrial pipelines, and fire equipment. It helps customers break through efficiency bottlenecks and seize the high-end market!

Technical highlight: Unveiling the 'hardcore technology' of the production line

1. Intelligent linkage, efficiency leap

Copper bar cutting machine+bar material lifting machine: precise cutting and seamless feeding, reducing manual intervention and improving raw material utilization.

Heating furnace+five axis robotic arm: Intelligent temperature control heating ensures material ductility, and the robotic arm accurately grasps to achieve "zero error" feeding in high-temperature environments.

2. Precision molding, quality assurance

High speed punching machine+edge cutting machine: Multi station molds can be quickly switched, and complex valve bodies can be stamped and formed in one go, improving the smoothness of edge cutting.

Multi station CNC lathe: integrated turning, drilling, and tapping, with a tolerance accuracy of ± 0.01mm, meeting international standards.

3. Surface treatment upgrade

Shot blasting machine: Customized abrasive formula, removes oxide layer while enhancing surface adhesion, laying the foundation for subsequent electroplating/spraying.

Core advantage: Why choose this production line?

Flexible production: Supports quick switching between various specifications such as DN15-DN300, ball valves/gate valves/angle valves, and more, making it easy to handle bulk customized orders.

Cost reduction and efficiency improvement: Per capita production capacity increased by 3 times, defect rate reduced to below 0.5%, and comprehensive cost savings of 30%.

Green intelligent manufacturing: equipped with a waste recycling system to achieve low-carbon production.

Application scenario: Empowering global customers

Bathroom hardware enterprises: quickly respond to the precision machining needs of high-end faucets and angle valves.

Industrial valve manufacturer: meets the stringent process requirements of high-pressure valves in the petrochemical and energy industries.

OEM/ODM OEM factories: flexibly adapt to customer drawings and shorten the sampling cycle.